This post provides plans and construction manual for my "Awkward

Fisherman Machine". It is a flying

pendulum, designed as a fisherman constantly throwing the line onto a

tree. Driven by a sinking weight, the sculpture runs for several

minutes with its continuously fruitless attempts. Watch a video of the

sculpture below.

Contents

1. Materials and Tools

2. PDF Plans for download

3. Construction Manual

1. Materials and Tools

Materials

- Plywood or fiberboard (thickness 3mm, ≈ 15 cm x 20 cm)

- Wood strip 5 x 20 mm (≈ 50 cm long)

- Wood strip 10 x 10 mm (≈ 10 cm long)

- Brass wire, ⌀ 3 mm

Optionally: steel wire ⌀ 2 mm or bicycle spoke for the "tree", makes the sculpture run slower due to the smaller diameter - Brass wire, ⌀ ≈ 1.5 mm

- Brass tube, inner ⌀ 3 mm

Be sure that the tube fits loosely onto the 3 mm brass wire - 2 weights, like a small (≈ 1 g) and a large (≈ 20 g) screw or nut, or something more pretty

- Roundwood or wooden skewer, ⌀ 3 mm, optional.

- Robust cotton thread

- Standard craft wire, ⌀ 0.5 mm - 1 mm

- Wood glue (PVA glue)

- Superglue or all-purpose adhesive

- Paper glue pen

- Soldering tin, soldering flux

Tools

- Handsaw (I perfer a Japanese saw)

- Jigsaw or scollsaw

- Hacksaw

- Comb pliers

- Drilling tool

- Drills, ⌀ 3mm, ⌀ 2mm

- Soldering iron

- Clamps for gluing

- Sandpaper (fine ≈ P100, very fine ≈ P220)

- Black-white printer

2. PDF Plans for download

Plans for the wood parts are available for download as PDF.

|

| Figure 1: Plans for The Awkward Fisherman Machine. Use high quality PDF for printing. Download PDF. |

3. Construction Manual

Step 1: Printing the plans

Download the PDF plans. Print the plans on A4

paper. Cut off headings and material list to get only the plans of the

wood parts.

Step 2: Gluing or transferring plans onto plywood

Glue the printed plans sheet onto a piece of plywood or fiberboard. Use

a water-soluble paper glue pen.

Alternatively, you can transfer/draw the plans onto the wood.

Alternatively, you can transfer/draw the plans onto the wood.

Step 3: Sawing out the parts

Saw out parts 1, 2, 4 and 5

using a handsaw. Carefully saw part 3 out of part 2 using the jigsaw or

scollsaw.

Step 4: Drilling

Drill the holes into parts 1, 3,

4 and 5 using a 3 mm drill. Use a 3 mm or 2 mm drill for the hole in

part 2, depending on whether you use 3 mm brass wire or 2 mm steel wire

for the tree.

Step 5: Removing plans from plywood

To remove the paper from the

sawed out parts, moisten it, wait half a minute or so, and peel it off.

Remove remains using the very fine sandpaper.

Step 6: Sawing and drilling the wood strip parts

Saw the wood strip parts according the list on the plans sheet.

Drill 3 mm holes through two of the small (20 mm x 10 mm x 10 mm) wood pieces, right next to the center (see Figure 2, top right).

Drill 3 mm holes through two of the small (20 mm x 10 mm x 10 mm) wood pieces, right next to the center (see Figure 2, top right).

Step 7: Cutting the metal parts

Cut the brass wire parts according the list on the plans sheet

using either hacksaw, comb pliers or your drilling tool. Cut the brass

tube using either hacksaw or drilling tool. Do not use pliers

for the tube!

Deburr all metal parts thoroughly.

Deburr all metal parts thoroughly.

You should now have all the parts shown in Figure

2.

|

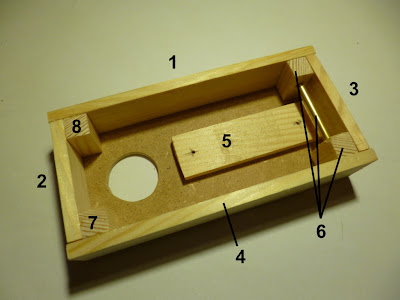

| Figure 2: Parts of the Awkward Fisherman Machine. |

Step 8: Assembling the box

Glue the wood strip parts onto part 2 according Figure

3 using wood glue. Follow the instructions you find on the glue.

Assemble in the order given in Figure 3 up to number 5. Start with a long piece of wood (1), next the pieces along the short edges (2, 3), then the second long edge (4) and the central piece (5). The central piece should cover the small hole in piece 2

Assemblage step 6 (Figure 3) has to be done all at once. Put the brass tube over the 50 mm brass wire, and plug one of the small, drilled pieces onto each end of the wire. Having the longer ends of the small pieces pointing downwards, glue everything into the "box" as shown.

Finally, add the two other small pieces (7, 8).

Assemble in the order given in Figure 3 up to number 5. Start with a long piece of wood (1), next the pieces along the short edges (2, 3), then the second long edge (4) and the central piece (5). The central piece should cover the small hole in piece 2

Assemblage step 6 (Figure 3) has to be done all at once. Put the brass tube over the 50 mm brass wire, and plug one of the small, drilled pieces onto each end of the wire. Having the longer ends of the small pieces pointing downwards, glue everything into the "box" as shown.

Finally, add the two other small pieces (7, 8).

|

| Figure 3: The partially assembled base of the sculpture. |

Step 9: Preparing the cover

Put part 1 on the open side of the assembled box so that the hole in

part 1 is near the brass parts. Drill a 3 mm hole through each corner

of part 1 and into the small wood pieces (see Figure

4 for the desired result). Widen the holes in the wood pieces a bit

(but not those in part 1). Glue a 1 cm long pieces of 3 mm roundwood

(you can also use the 3 mm brass wire) into each of the 4 holes of part

1. Carefuly plug part 1 in place before the glue is dry to make sure it

fits afterwards.

|

| Figure 4: The completely assembled base of the sculpture. |

Step 10: Installing "bearings" and "turntable"

Glue part 4 into the box over the large hole in part 2 (See Figure

4). Take care that the hole in part 4 is centered in the large hole.

Close the box with the cover (after drying) and turn it with the cover down. Plug part 3 (small disk) onto one end of the 25 mm brass wire. Next, plug the wire with disk into the large hole of the box. Adjust the position of the disk on the wire to have approx. 1 mm space between the disk and the ground of the large hole (see Figure 5, the upper level of the disk is slightly over the box).

Adjust disk and wire to have the wire exactly vertical and make sure they can spin freely. Hammer onto the upper end of the wire to mark its position on the cover. Take off the cover and glue part 5 onto the inner side of the cover (see Figure 4), fitting the hole in part 5 to the marking produced in the previous step.

Close the box with the cover (after drying) and turn it with the cover down. Plug part 3 (small disk) onto one end of the 25 mm brass wire. Next, plug the wire with disk into the large hole of the box. Adjust the position of the disk on the wire to have approx. 1 mm space between the disk and the ground of the large hole (see Figure 5, the upper level of the disk is slightly over the box).

Adjust disk and wire to have the wire exactly vertical and make sure they can spin freely. Hammer onto the upper end of the wire to mark its position on the cover. Take off the cover and glue part 5 onto the inner side of the cover (see Figure 4), fitting the hole in part 5 to the marking produced in the previous step.

|

| Figure 5: The completely assembled base with turntable from top. |

Step 11: Sanding

Sand the box, cover and disk to

have a smooth surface and rounded edges and corners. Start with the

coarser sandpaper for corners and edges and end with the finer for the

entire surface.

Step 12: Preparing visible metal parts

Cut and bend all parts for the figure from brass wire using pliers. I

recommend to use one piece of 3 mm brass wire for the body as well as

for each foot and the 1.5 mm wire for the rest. Using one piece for

both legs, one for both arms and one for the head should work well. See

Figure

6 for details. The final figure should be approx. 6 cm high.

Use a long piece (220 mm - 250 mm) of 3 mm brass wire, 2 mm steel wire or a bicycle spoke to form the tree. Make sure the stem of the tree is at least 10 cm long. If you use a bicycle spoke, have the thread at the bottom end of the stem.

Use a long piece (220 mm - 250 mm) of 3 mm brass wire, 2 mm steel wire or a bicycle spoke to form the tree. Make sure the stem of the tree is at least 10 cm long. If you use a bicycle spoke, have the thread at the bottom end of the stem.

|

| Figure 6: The final fisherman figure, depicting the necessary parts. |

Step 13: Soldering

Soldering the small parts of the figure works best if you fix

everything in place first. I use a block of wood with lots of small

holes and craft wire, as shown in Figure

7.

Before soldering, roughen all contact points and apply soldering flux. If you wave no soldering experience, please inform yourself elsewhere.

Before soldering, roughen all contact points and apply soldering flux. If you wave no soldering experience, please inform yourself elsewhere.

|

| Figure 7: The parts of the figure, fixed for soldering. |

Step 14: Installing metal parts

Drill through the small (2 mm or 3 mm) hole on top of the box into the

piece of wood glued over that hole from inside. Glue the tree into the

hole using superglue (or screw it in case you used a bicycle spoke).

Glue the feet of the figure onto the small disk, also with superglue. For the final arrangment, see Figure 8.

Finally, cut a piece of 1.5 mm brass wire for the fishing rod and bend one of the ends to a small loop. Solder the fishing rod onto the hands of the figure. The loop end of the rod should be a few millimeters away from the tree stem in its closest position (see Figure 8). During soldering, take care that the figure does not heat up too much and break apart.

Glue the feet of the figure onto the small disk, also with superglue. For the final arrangment, see Figure 8.

Finally, cut a piece of 1.5 mm brass wire for the fishing rod and bend one of the ends to a small loop. Solder the fishing rod onto the hands of the figure. The loop end of the rod should be a few millimeters away from the tree stem in its closest position (see Figure 8). During soldering, take care that the figure does not heat up too much and break apart.

|

| Figure 8: The completely assembled Awkward Fisherman Machine. |

Step 15: Fixing threads and weights

Glue a long peace of cotton thread (approx. 1 m) onto the pivot under

the figure while it is in place in the box (see Figure

4). Feed the thread through the gap between the box and the brass tube

like in Figure

4, and through the hole in the cover. Finally, close the cover and fix

the larger weight at the end of the thread.

Fix the smaller weight to the loop of the fishing rod using thread. When hanging down, the weight should be a few millimeters above the top of the base.

Fix the smaller weight to the loop of the fishing rod using thread. When hanging down, the weight should be a few millimeters above the top of the base.

Finally: testing the machine

To wind the machine up, take the small weight and use it to rotate the

figure around it's axis until the large weight hangs directly below the

box. Alternatively, you can wind the thread of the small weight around

the fishing rod and use your index finger to rotate the figure.

Place the sculpture on the edge of a table, so the weight can sink down freely, and release the fishing rod.

Place the sculpture on the edge of a table, so the weight can sink down freely, and release the fishing rod.

Enjoy tinkering! Your feedback is welcome.

Yours sincerely,

Turnvater Janosch

Excelente, me gustó mucho y lo voy a realizar, muchas gracias por los planos.

ReplyDeleteHi Mr Turnvater Janosch my name is Milton I am from Venezuela, and I saw your marble clock, and enjoy it, can you send yours plans to me,

ReplyDeleteI want to build one.

thanks

jimufa@gmail.com

Do u have this for sale. I would like to buy one

ReplyDelete